Purpose of Water level control system

The drinking water crisis in Bangladesh is reaching alarming proportions. It might very soon attain the nature of the global crisis. Hence, it is of utmost importance to preserve water. In many houses, there is unnecessary wastage of water due to overflow in Overhead Tanks. Automatic Water Level Controller can provide a solution to this problem. The operation of water level controller works upon the fact that water conducts electricity. So water can be used to open or close a circuit. As the water level rises or falls, different circuits in the controller send different signals. These signals are used to switch ON or switch OFF the motor pump as per our requirements.

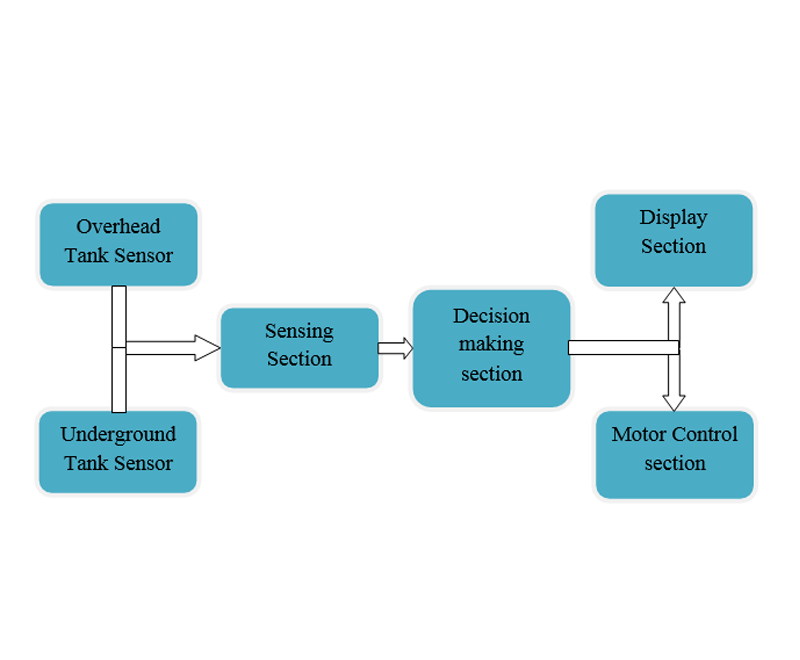

Fig: Work Processing block diagram

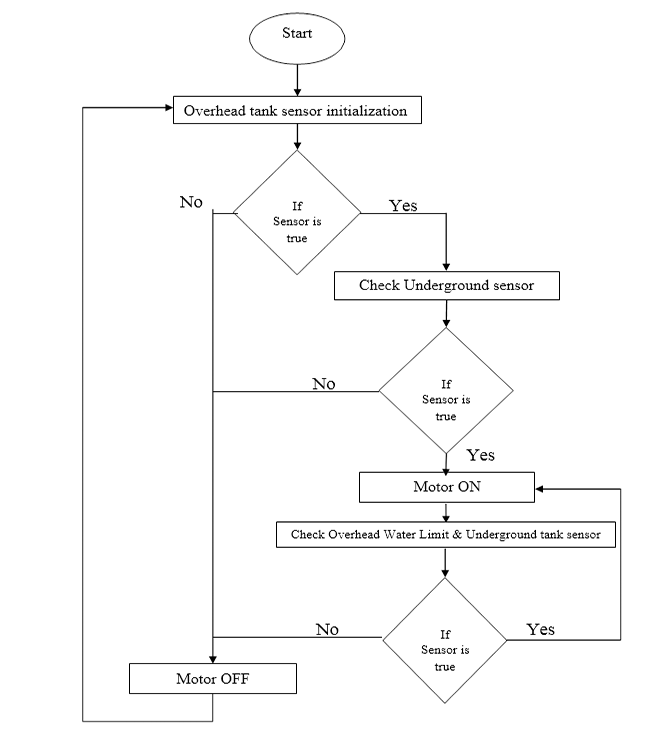

Flowchart of the proposed Water Level controlling system

Working Principle:

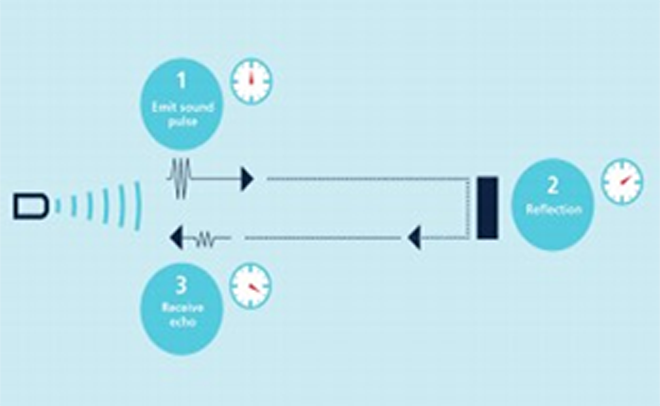

This water level indicator uses an ultrasonic sensor to determine the level of water in the tank. The ultrasonic sensor measures distance using sonar. An ultrasonic (well above human hearing) pulse is transmitted from the unit and distance-to-target is determined by measuring the time required for the echo return. An output from the ultrasonic sensor is a variable-width pulse that corresponds to the distance to the target. This is then fed to the microcontroller that determines the water level and displays it through a series of LEDs or LCD display.

Function of Ultrasonic sensor

ultrasonic sensors emit short, high-frequency sound pulses at regular intervals. These propagate in the air at the velocity of sound. If they strike an object, then they are reflected back as echo signals to the sensor, which itself computes the distance to the target based on the time-span between emitting the signal and receiving the echo.

As the distance to an object is determined by measuring the time of flight and not by the intensity of the sound, ultrasonic sensors are excellent at suppressing background interference. Virtually all materials which reflect sound can be detected, regardless of their color. Even transparent materials or thin foils represent no problem for an ultrasonic sensor. microscopic ultrasonic sensors are suitable for target distances from 20 mm to 10 m and as they measure the time of flight.

Fig:Ultrasonic sensor principles

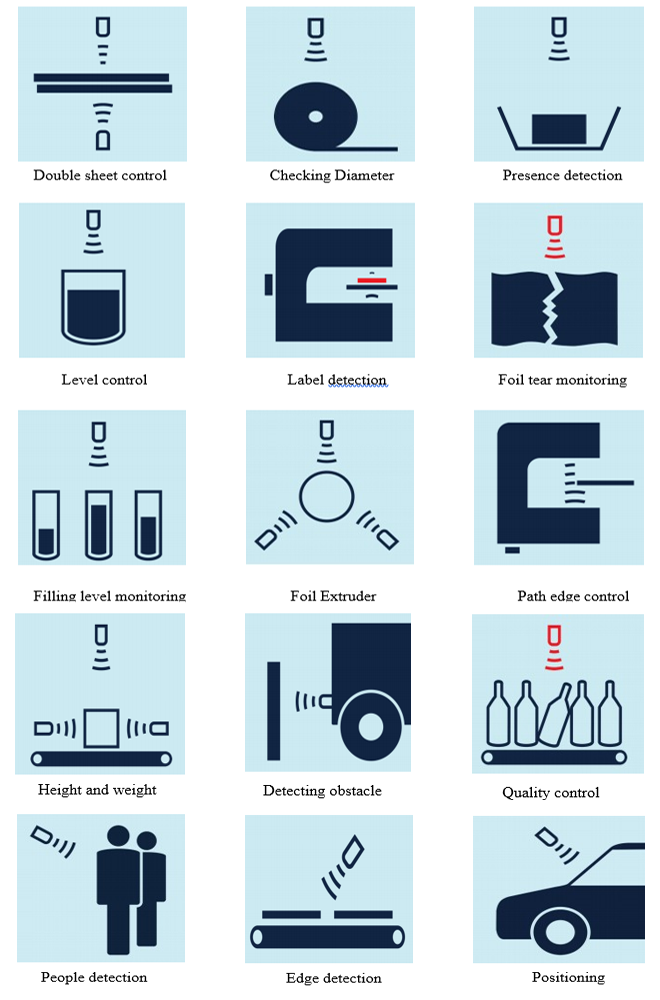

Ultrasonic sensors are suitable for the automated detection of positions and distances of objects. Their function is independent of the surface characteristics of the target object. Pulsotronic ultrasonic sensors are working with ultrasonic converters for sending and receiving. In a determined cycle, the sensor is sending special encoded ultrasonic signals. After the reflection at the target object, the sensor is receiving and decoding the signals. The determined signal delay is processed into a distance information and temperature compensated. High carrier frequencies as well as the most modern signal processing guarantee that the sensors are working failure-free and accurately. For transmission to a process control computer analog, digital or switching outputs are used as well as RS232 and RS485 interfaces. Via synchronization units, multiple sensors can be used at the same time. Because of this, the scanning of structures with sensor arrays is possible.

Possible Industrial Application

The advantage of the Water level controlling system:

Techsense Bangladesh Ltd.

Cell: +8801974177909, Email: [email protected]

Road#30, House#423(4th floor), Mohakhali DOHS, Dhaka

আমি রেজাউল করিম সিদ্দিকী। বিশ্বের সর্ববৃহৎ বিজ্ঞান ও প্রযুক্তির সৌশল নেটওয়ার্ক - টেকটিউনস এ আমি 7 বছর যাবৎ যুক্ত আছি। টেকটিউনস আমি এ পর্যন্ত 2 টি টিউন ও 0 টি টিউমেন্ট করেছি। টেকটিউনসে আমার 1 ফলোয়ার আছে এবং আমি টেকটিউনসে 0 টিউনারকে ফলো করি।